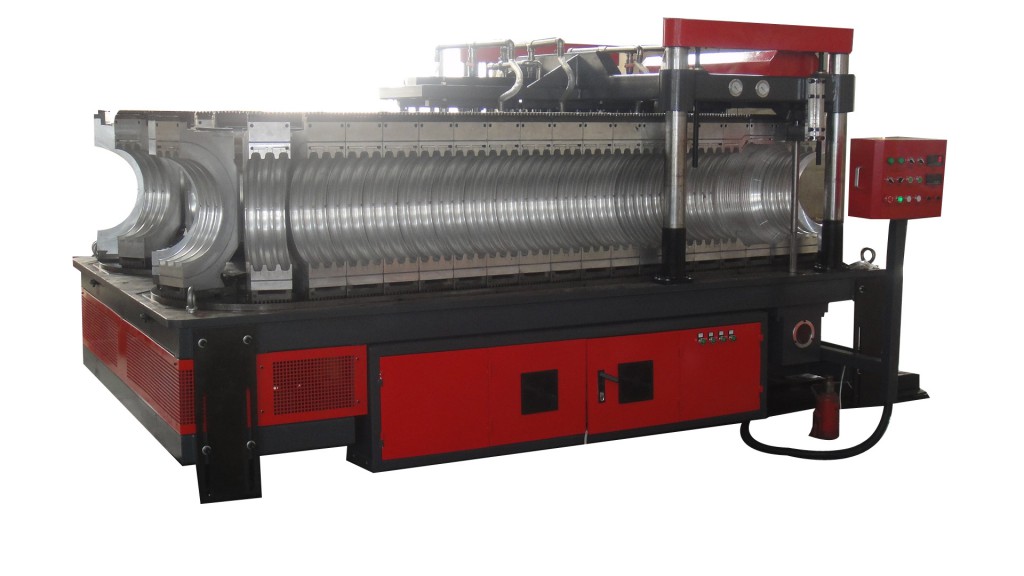

SGB500(inner diameter Φ200-500mm) double wall corrugated pipe production line has two single-screw extruder. It has a dual-channel structure and nitriding polishing head. The forming machine adopts horizontal structure, chain drive design, advanced water cooling system, vacuum forming system, automatic lubrication system and advanced double-layer on-line expansion function. The material of the molds is aluminum alloy. The complete production line uses the German Siemens production of professional PLC control system. It has a high degree of automation, reliable operation, easy operation and so on.

The production line uses HDPE / PP as raw materials. The inner wall of the double wall corrugated pipe produced by this production line is very smooth and flat. And the outer wall is trapezoidal corrugated shape. This kind of double wall corrugated pipe has the characteristics of good corrosion resistance, high insulation, small flow resistance etc. as the ordinary plastic pipe, but also because of special inner and outer wall hollow ring structure, it has the advantages of high rigidity, light weight, high pressure resistance, good toughness, abrasion resistance, impact resistance, not easy damage, convenient construction, low installation cost, long service life etc. The double wall corrugated pipe is generally connected by the expansion socket and the sealing ring. This can effectively prevent the impact of thermal expansion and contraction. The double wall corrugated pipe is widely used in the fields of highway, railway roadbed, subway engineering, waste landfill, tunnel, green belt, sports field and high water content caused by the slope protection and other drainage areas.

The characteristics of HDPE/PP double wall corrugated pipe production line:

SGB500 double-wall corrugated pipe production line is the Jiangsu-Machinery Co., Ltd. according to the needs of the market, absorbing the same industry at home and abroad advanced technology in the field of plastic extrusion made the latest research results. The whole production line is suitable for high speed extrusion of HDPE, LDPE, PP and other raw materials. The production line adopts direct extrusion (dual coextrusion) forming processing and man-machine interface control system. It has high degree of automation, reliable quality and stable operation. It is famous in the world.

1. The double wall corrugated pipe extrusion line uses two high-speed single-screw extruders. Single-screw extruder: We use PE high-speed high-efficiency single-screw extruder. Its barrel is slotted type design. It is also equipped with a low-noise fan and a high-speed hard-surface gear box. The inner and outer layers of the double wall corrugated pipes are independently fed by two extruders. It achieves the use of different colors and different raw materials production, and ensures efficient extrusion.

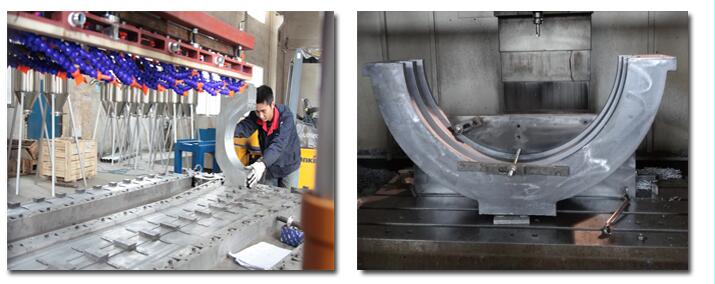

2. Extrusion mold: It has dual flow channel structure. It goes through the nitriding and polishing process. The special design of the die is suitable for the production of different materials and different ring stiffness pipes. The special mold structure ensures that the inner and outer layers are evenly and stably formed.

3. Forming machine: It adopts horizontal structure and chain drive design. At the same time, it is also equipped with an open water cooling system and a vacuum forming system. This ensures a high production rate for continuous production. The mold adopts the mechanical up and down synchronous drive and the advanced programmable lubrication system. These make the molds have a long service life, ensure the accuracy of the operation and ensure the quality of the pipe. Because of using advanced online expansion function, we can expand the double wall corrugated pipe online. This significantly reduces the investment and the improves production efficiency.

4. Molds: The corrugated forming module is made of special alloy material through precision casting. It has high precision, strength, wear resistance and excellent heat dissipation effect. By using advanced module rapid replacement system, the replacement time of the module is greatly reduced. According to the different requirements of different customers , we can design different wave type forming module.

5. The control system of production line:

We use the German Siemens production of professional PLC control system and large-screen touch man-machine interface. So it makes the complete line have the characteristics of a high degree of automation, reliable operation, easy operation and so on.

Model | SGB800 | SGB600 | SGB500 | SGB250 | SGB160 |

Structure Form | Vertical | Vertical | Horizontal | Horizontal | Horizontal |

Materials | Particle / powder | Particle / powder | Particle / powder | Particle / powder | Particle / powder |

Applicable Raw Materials | HDPE/FRPP/PVC | HDPE/FRPP/PVC | HDPE/FRPP/PVC | HDPE/FRPP/PVC | HDPE/FRPP/PVC |

Pipe Diameter Range | 225-800mm | 250-600mm | 200-500mm | 110-250mm | 75-160mm |

Max Extrusion Output | 850kg/h | 700kg/h | 600kg/h | 350kg/h | 200kg/h |

Expansion Mode | Belling-on-line,double-wall socket joint | Belling-on-line,double-wall socket joint | Belling-on-line,double-wall socket joint | Belling-on-line,double-wall socket joint | Belling-on-line,double-wall socket joint |

Forming Speed | 0.25-3m/min | 0.25-4m/min | 0.25-4m/min | 0.5-5m/min | 0.6-5m/min |

Centre Height | 1600mm | 1600mm | 1150mm | 1150mm | 1000mm |

Number of Mold Blocks(pairs) | 32 | 32 | 40 | 48 | 48 |