Introduction:

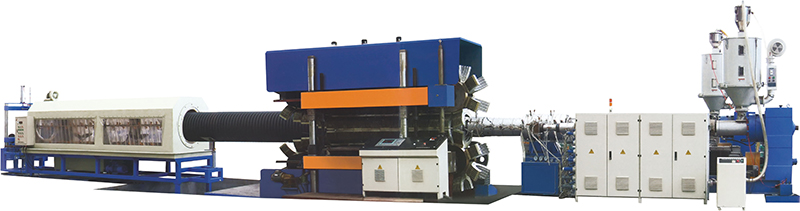

1. The PE double wall corrugated pipe forming machine has high capacity as well as stable operation. It is a core part of the production line with pipe diameter between 200mm to 800mm.

2. Forming machine adopts horizontal structure, shuttle transmission, seal water cooling, vacuum forming, unique original online double flared vacuum system architecture, emergency back function.

3. Machine electrical system apply touch-screen system, intuitive, advanced, high operability.

4. Forming machine use automatic reset function. It is possible to restore the original position in case of a sudden power failure, out of the nose and aluminum module with a security role.

Final products introduction:

HDPE double-wall corrugated pipe use the high density polyethylene as the main raw material, jointly extruded from inside and outside the extruder, forming a smooth inner wall, an outer wall trapezoidal corrugated wall hollow layer sandwiched between the inner and outer walls of plastic pipe.Final products has the advantages such as ring stiffness, strength, light weight, noise damping, high stability, long life, good flexibility, pressure high impact strength and so on.It can be laid in poor geological sections, and good sealing, fast construction.

Production line features:

1.The extrusion line equipped with two extruders, double coextrusion, extrusion material stability, good plasticizing.

2. Import proportional control valve to adjust the air pressure molding, stable and reliable.

3. The double channel spiral composite extrusion die, die polishing surface nitriding treatment.

4.Double wall thickness regulating device.

5.Online double pipe socket belling.

6.Lateral, horizontal and vertical three-dimensional adjustable table.

7.Workbench automatically exit the power protection system.

8.Module is made of special aluminum alloy, light weight, high strength, wear resistance, low coefficient of thermal expansion characteristics.

9.Forming module air-cooled and water-cooled, cooling effect is good, fast forming speed.

10.The whole production line adopts PLC microcomputer control system, visual display of melt temperature, pressure, forming speed, fault alarm, etc.11.Efficient single-screw extruder (using pellets) and energy-saving twin-screw extruder (using powder or pellets) for selection.

| Model | SGB800 | SGB600 | SGB500 |

| Structure Form | Vertical | Vertical | Horizontal |

| Materials | Particle / powder | Particle / powder | Particle / powder |

| Applicable Raw Materials | HDPE/FRPP/PVC | HDPE/FRPP/PVC | HDPE/FRPP/PVC |

| Pipe Diameter Range | 225-800mm | 250-600mm | 225-500mm |

| Max Extrusion Output | 850kg/h | 700kg/h | 600kg/h |

| Expansion Mode | Belling-on-line,double-wall socket joint | Belling-on-line,double-wall socket joint | Belling-on-line,double-wall socket joint |

| Forming Speed | 0.25-3m/min | 0.25-4m/min | 0.25-4m/min |

| Centre Height | 1600mm | 1600mm | 1600mm |

| Number of Mold Blocks(pairs) | 32 | 32 | 40 |